Is the supply chain crisis over? The short answer is no.

Since the pandemic, supply chain bottlenecks have been a massive, fluctuating issue for online retailers. And although Bloomberg predicted that they would stabilize by 2023, new geopolitical disruptions have resulted in further challenges.

The bottom line is that supply inconsistencies and disruptions are here to stay — and although there is a lot you can plan for, there is plenty you can do to weather any storm.

And the cost potential of being unable to stay on top of these supply chain disruptions? Some experts put the potential financial loss to as much as 62%.

This post highlights the top supply chain trends, challenges, and changes predicted for the coming year, as well as give you what you need to plan to face a volatile future with less financial disruption.

Let’s jump in.

1. Increasing Geopolitical Changes and Disruptions Push Nearshoring Trends

Unfortunately, geopolitical tensions and lack of trust between nations are a growing 2023 concern. And as we’ve seen with the Ukrainian–Russian war and COVID shutdowns, these international developments can profoundly affect material supply, logistical routes, and manufacturing — even on a local level.

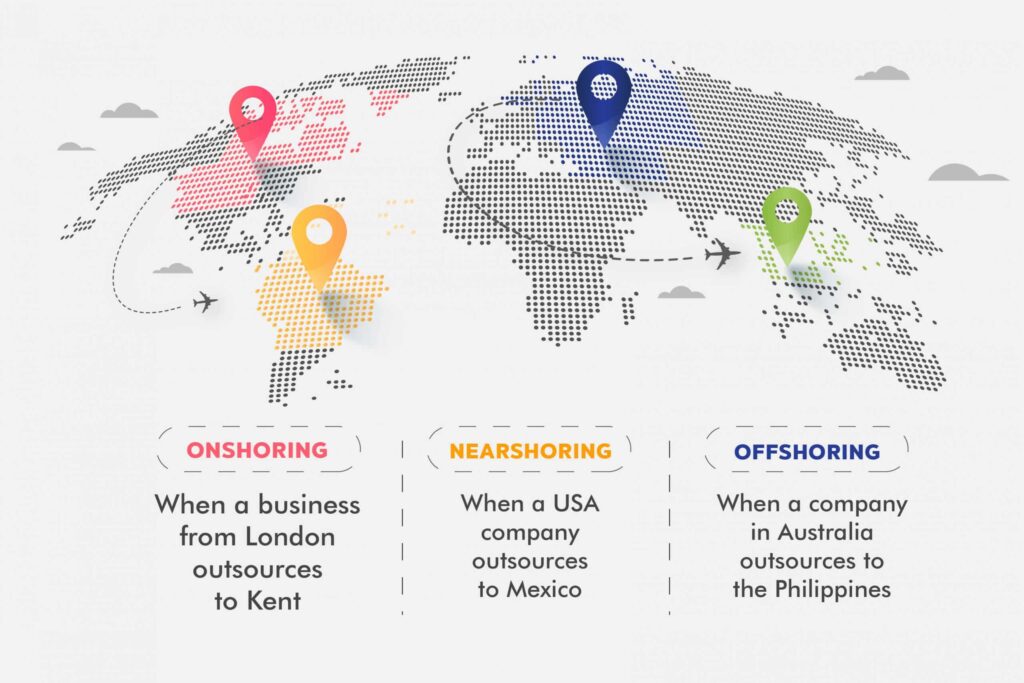

This has resulted in an increase in brands (as well as localities and nations) to focus on building onshoring and nearshoring (also often called friendshoring) supply chains — investing in domestic self-sufficiency regarding material supply and manufacturing.

[Source: Flexisource IT]

This is not a totally new trend. In fact, in July of 2021, the White House released a Building Resilient Supply Chains report that kickstarted the growing friendshoring logistics trend.

What does this mean for your store?

How to Prepare Your Store for Geopolitical Changes

With growing international unrest and uncertainties, you should review if your store could leverage nearshoring to secure your supply and logistics network — and how to do it.

However, it’s essential to understand that switching to these logistical and supply strategies could affect lead times, operational costs, and production speed. Therefore, before jumping in, you will want to:

- Layout scenarios where access to key materials or products would be shut off. Assess your backup plans and model financial and customer implications. Could you increase material stores first before having to change suppliers?

- Keep a close eye on geopolitical tensions that could affect your specific supply chain — changing strategies only when you absolutely need to.

- Implement strategies to enhance responsiveness, lead time, and operational costs now. This will help mitigate the losses that could result when first implementing new nearshoring logistics.

2. Expanding Digital Trends are Transforming Supply Chain Strategies

Three main digital trends that are likely to drive supply chain changes this year are:

- Smart logistics robotic solutions

- Big Data and advanced analytics

- AI and machine learning

As supply chain challenges increase, more eCommerce brands are investing in automation technologies that will help them better manage operational tasks, supply planning, and warehousing.

This, in turn, gives them access to advanced analytics they can use to further optimize their end-to-end supply chain strategies.

Ultimately, online retailers are racing to ensure their supply chain and operational capacities win in terms of real-time optimization and efficiency improvement. Not just for supply chain optimization during bottlenecks but in fighting rising eCommerce costs.

How to Prepare Your Store for Expanding Digital Trends

Front and backend automation will be critical when it comes to decreasing costs while boosting efficiency this year.

Although many online stores have been investing heavily in frontend automation, such as PPC automation, they are still falling short on logistical, operational, and supply chain technology investment — technologies they will need to compete.

This is especially important when you want to improve supply chain visibility; the ability to clearly track all your materials and products in transit. This task is very labor-intensive without digital optimization.

Here are a few tips on how to choose and integrate new technologies:

- Prioritize supply chain planning tools that help you maintain some operational efficiency and stability in the face of distributions. Or, you could outsource fulfillment to a service like FedEx that offers integrated supply chain solutions and consulting.

- Consider which inefficient manual supply chain activities you can replace with automation to increase productivity and protect against rising costs — while minimizing human errors.

- Invest in automation that will help you maintain supply chain visibility to enable better product tracking and supplier/merchant communication for less cost — preventing mistakes that could result from costly mistakes or labor.

[source: xChange]

3. Balancing Customer Expectations with Unexpected Delays

Here’s the thing; you can’t wait for the supply chain crisis to be over. If you want to hang onto market dominance, you must fix possible vulnerabilities now — not when the next unforeseen challenge is.

The most significant effect of being unprepared is being unable to balance customer expectations for fast delivery with sudden bottlenecks. However, preparing for surprise things that could or might happen is a real challenge.

So, what can you do?

How to Prepare Your Store for Supply Chain Bottlenecks Without Shattering Expectations

There are three ways brands should be tackling this:

- Rethinking on-hand inventory strategies

- Forgoing single-sourcing procedures and instead turning to multiple suppliers

Let’s first talk stock on hand.

The more available stock you have to meet your customer’s needs, the more able you are to meet their expectations and the less likely they are to go to a competing brand. But you will want to do this slowly to avoid overstocking, which could eat away at necessary capital.

This is not a new fix. From early 2021, many Shopify Plus merchants started carrying more inventory to weather the supply chain crisis — with up to 80% of all merchants doing the same by the spring of 2022. However, with inflation concerns growing, brands also need to now consider market shifts and economic downturns.

Another way you can keep up with customer expectations, regardless of what challenge comes around the corner, is by ensuring that you diversify your product sources.

Instead of focusing on cost alone, you need to look for suppliers known for their resilience and with backups in place. Even better if you look locally for as many product and material sources as possible — this is what 31% of Shopify merchants are already doing.

Ultimately, with both strategies, you are looking for supply chain flexibility.

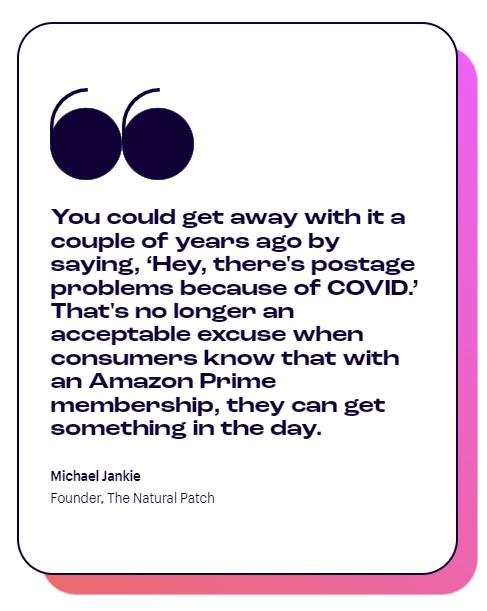

This is something The Natural Patch has been able to achieve perfectly by leaving a healthy buffer of around three months of inventory to counteract any air freighting supply delays or make up for increased demands on peak holiday shopping days.

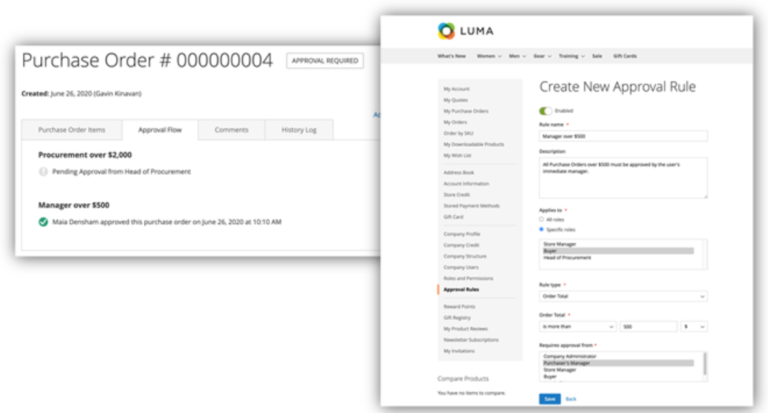

[Source: Shopify]

4. Shifting Focus from Delivery Time to Brand Loyalty

We know that supply chain issues can negatively affect brand loyalty. However, brand loyalty will also get you through your next challenge.

Yes, availability and delivery time are still critical, but not to the detriment of customer satisfaction — especially if it means increasing prices to counteract rising delivery costs caused by supply chain disruptions.

However, if you want to not only survive, but thrive (despite any delays or cost increases supply challenges may cause), brand loyalty is key. Additionally, the benefits of increasing loyalty and satisfaction include:

- Lowering your return rates

- Keeping customers engaged even when you are out of stock

Both of which affect long-term growth.

And when you add that to rising costs and inflation-induced slower spending, hyper-focusing on building loyalty rather than only on micro-managing margins will be important.

How to Protect Your Store from Supply Chain Bottlenecks with Loyalty Strategies

You need to plan ahead to create supply chain flexibility by focusing on your shoppers and how to serve them better. This means having a lot of long-term and short-term strategies in place.

The first place to start is by ensuring you have formulated strategies to maintain satisfaction despite shipping delays. This means:

- Rewarding customer patience with a well-timed discount in the event of unforeseen delays

- Building a robust automation system that keeps customers informed at every step

- Being completely transparent with expected delays and timetables

- Investing in out-of-stock notifications or pre-sale store capabilities.

(If you’re on Shopify, apps such as Amai’s PreOrder Manager + Notify will help you do the latter. Or you can use order management system like Brightpearl.)

Additionally, in the background, you must ensure you build loyalty through every step of your eCommerce sales funnel. The more customers value and trust your brand, the more likely they will wait for a product that is out of stock — instead of going to your competitors.

5. Dealing with Increased Consumer Demands in the Face of Supply Chain Disruptions

Here’s the hard truth: Many of your shoppers won’t wait for the recovery of supply chains. This is especially true if you’re selling in a highly competitive market where alternatives are plenty.

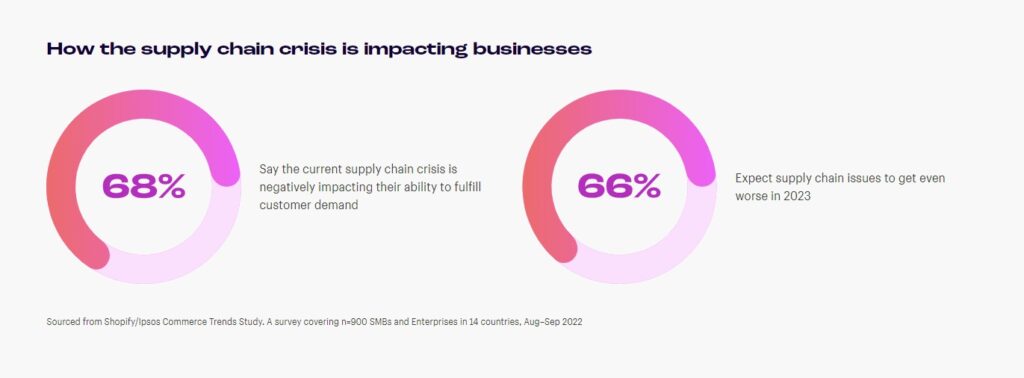

Shopify surveyed over 900 global brands and found that 68% of sellers are finding supply issues are negatively impacting their ability to deal with consumer demands, and over 65% of them predict this problem will progress through this year.

[Source: Shopify]

Therefore, it is vital that you invest in ways to meet increased demand and expectations, despite any further supply chain challenges.

How to Prepare Your Store for Increased Demand When Supply Slows

The three strategies you can put in place to help you deal with increased demand during supply struggles are:

- Holding more inventory

- Diversifying your suppliers

- Shrinking your return rates

Let’s talk about return rates specifically.

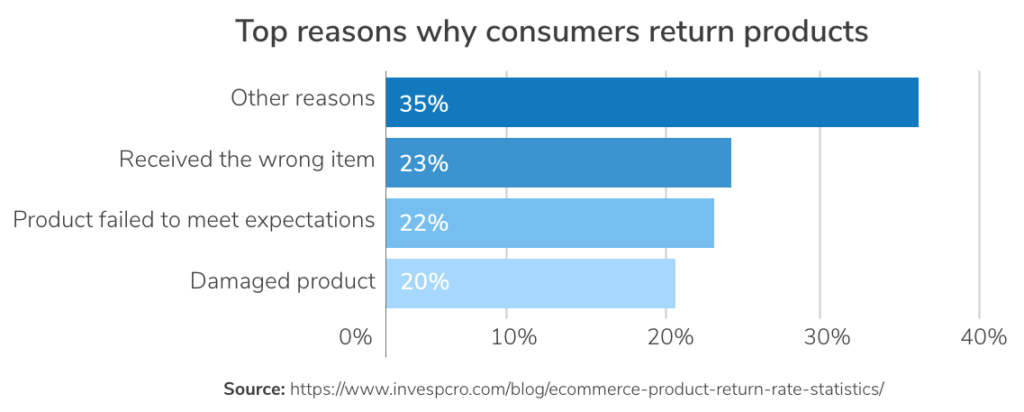

Over the last eight years, the loss per customer has increased by a whopping 220% — with brands losing $29, on average, for each newly acquired shopper. This is particularly concerning for eCommerce, as return rates can be as high as 50%, as opposed to the 10% highs of in-store purchases.

The bottom line is that the lower your return rates are, the happier your customers are, and the more profitable you will be. This means tackling the three main reasons for returns with counter strategies — products that:

- Arrive damaged

- Don’t meet expectations

- Aren’t the correct item/size

Optimizing your product pages to ensure descriptions are accurate and detailed and that they include high-quality product images or videos and accurate size charts, are a must. You will also want to consider investing in augmented reality.

Another tactic worth trying is adding a fee for returns — however, you need to build up a strong brand following before testing. Zara UK, for instance, began to implement fees in 2022 to counteract the high return rates for online purchases.

However, this is only for online returns. To encourage in-store shopping, online returns cost European customers £1.95 ($2.34), while in-store returns are still free — and they are not alone.

Here are stores that now charge for returns, according to Footwear News:

- Foot Locker

- Abercrombie & Fitch

- Boohoo

- DSW

- JCPenney

- Kohl’s

- L.L. Bean

- Urban Outfitters

- Uniqlo

- Belk

- Shoe Carnival

- REI

- Next

- Journeys

- Dillard’s

6. Rising Supply Chain and Fulfillment Costs

As we touched on earlier in this post, rising inflation is affecting most aspects of eCommerce, including supply chain and logistics operations. But it’s not the only economic factor that could disrupt supply chains this year.

Rising fuel prices, workforce shortages, and lack of material access (including those to fix manufacturing machinery) all lead to lower productivity and higher operational costs. When you add that to downward consumer spending trends, simply raising prices is not always an option.

How to Prepare or Protect Your Store for Rising Costs

There are two things you can do to help alleviate the pressure of rising supply chain and fulfillment costs. That is:

- Leveraging automation (which we outlined earlier)

- Diversifying your delivery options

Despite economic trends and supply chain disruptions, eCommerce is still growing substantially — so is shipping volume. Therefore, by diversifying your delivery partners, you have flexibility in terms of cost changes and availability.

This isn’t just about outsourcing — you also want to diversify your systems internally. For this, automation is key.

For instance, online pet store Chewy announced earlier this year that they would set up two additional automated fulfillment centers to expand capacity while simultaneously decreasing costs.

7. Increasing Cybercrime Risks

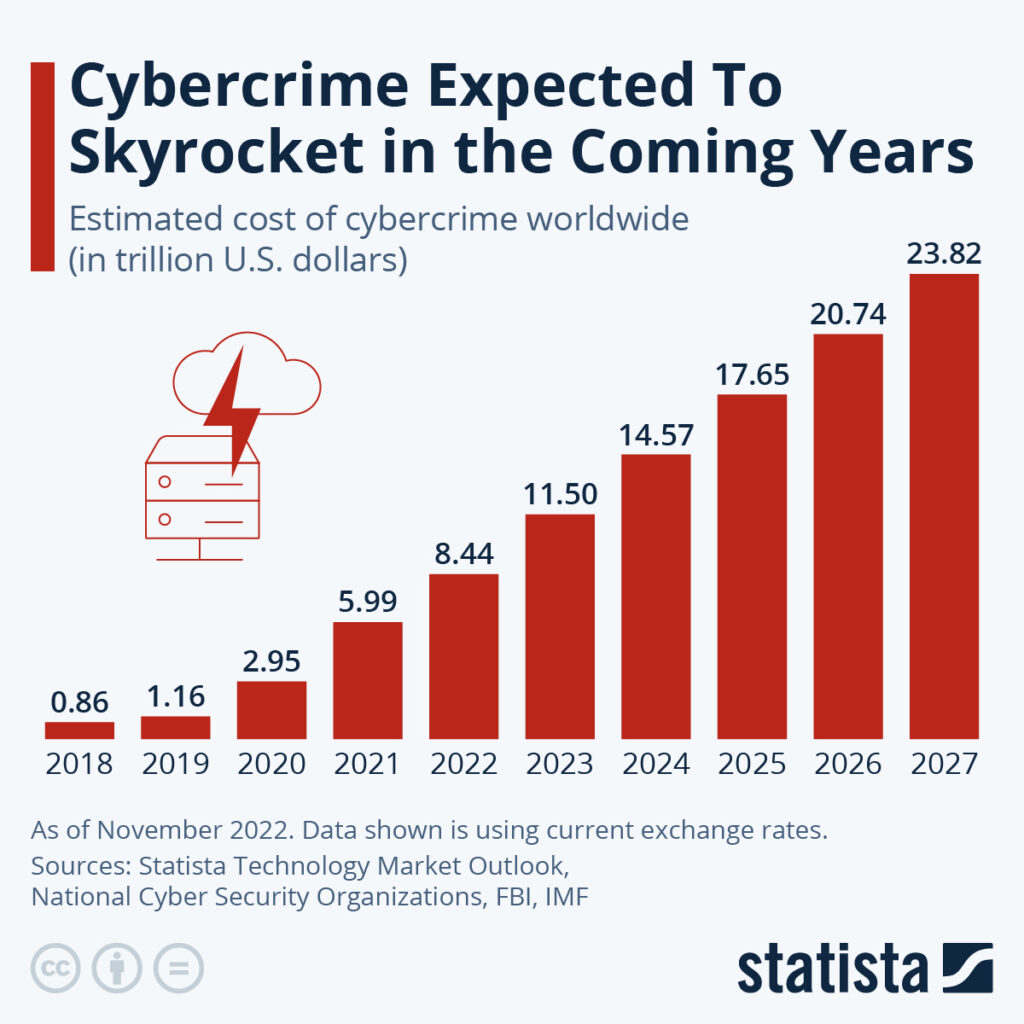

Another trend that could affect your supply chain operation this year is the rise in cybercrimes.

[Source: Statista]

They aren’t just increasing; they are getting more sophisticated.

By installing malware at any point of a supply chain, cybercriminals often try to tamper with manufacturing processes, which can cause outages and delays. Even if you’re outsourcing a lot of your manufacturing, they have been known to compromise even basic warehouse management equipment.

The bottom line is, no one is immune. But there are a few things you can do to mitigate some of the risks.

How to Protect Your Store from Increasing Cybercrime Risk

While you can’t control the systems your supplies have in place, you can ensure you choose vetted, reputable vendors. You can also make sure that you are doing everything you can internally to help protect your brand and supply chain systems.

There are two main mechanisms you can use to reduce the risk of cyberattacks on your systems internally.

- Automation. Automation tools can go a long way to protecting your brand — when you consider that as many as 95% of cyberattacks are caused by a human element/error. You may also want to invest in advanced AI and machine learning solutions when adding new suppliers. These can identify threats such as spam and phishing emails.

- Assessments. You will want to do regular risk assessments for all your functions/activities within the supply chain. (The best way would be to use an IoT device.) You will also want to ensure that any third-party tool or service you bring into your supply chain systems has also undergone risk assessment.

Wrap Up

To sum up, there are two things we know.

Firstly, supply chain challenges and changes are the new normal. Secondly, although we can’t plan for every possible scenario, we can lay the groundwork so that we can adapt to trends and shifts.

The best way to do just that is by using the tips highlighted above to build a flexible supply chain and backend operational strategy that has the ability to deal with any disruptions as quickly and efficiently as possible.

Got questions? Post them in the comments section below!

[Feature Image Source: Mika Baumeister]

Nicole Blanckenberg

Nicole is a content writer at StoreYa with over sixteen years experience and flair for storytelling. She runs on a healthy dose of caffeine and enthusiasm. When she’s not researching the next content trend or creating informative small business content, she’s an avid beachgoer, coffee shop junkie and hangs out on LinkedIn.

Comments

comments

Powered by Facebook Comments